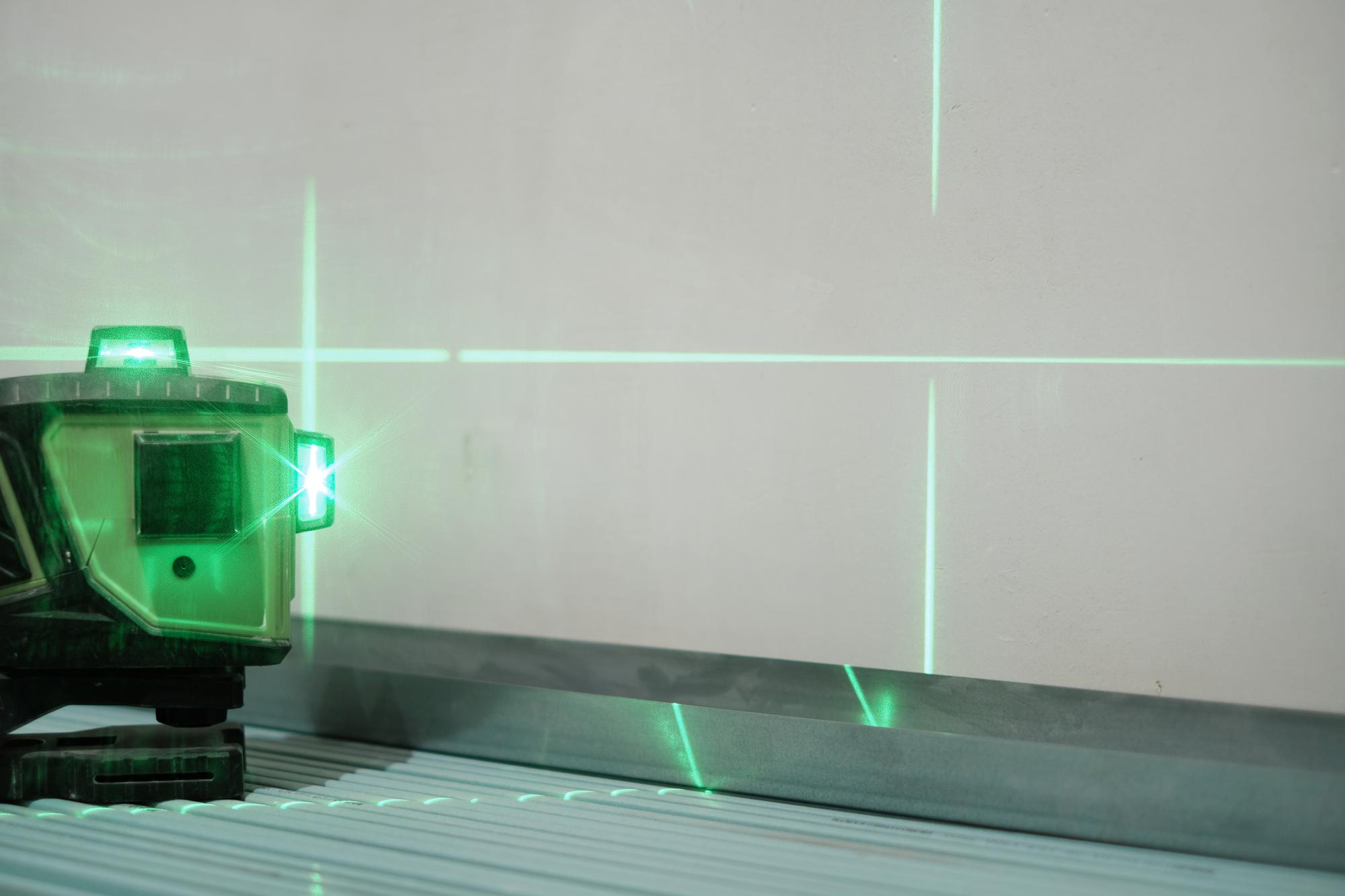

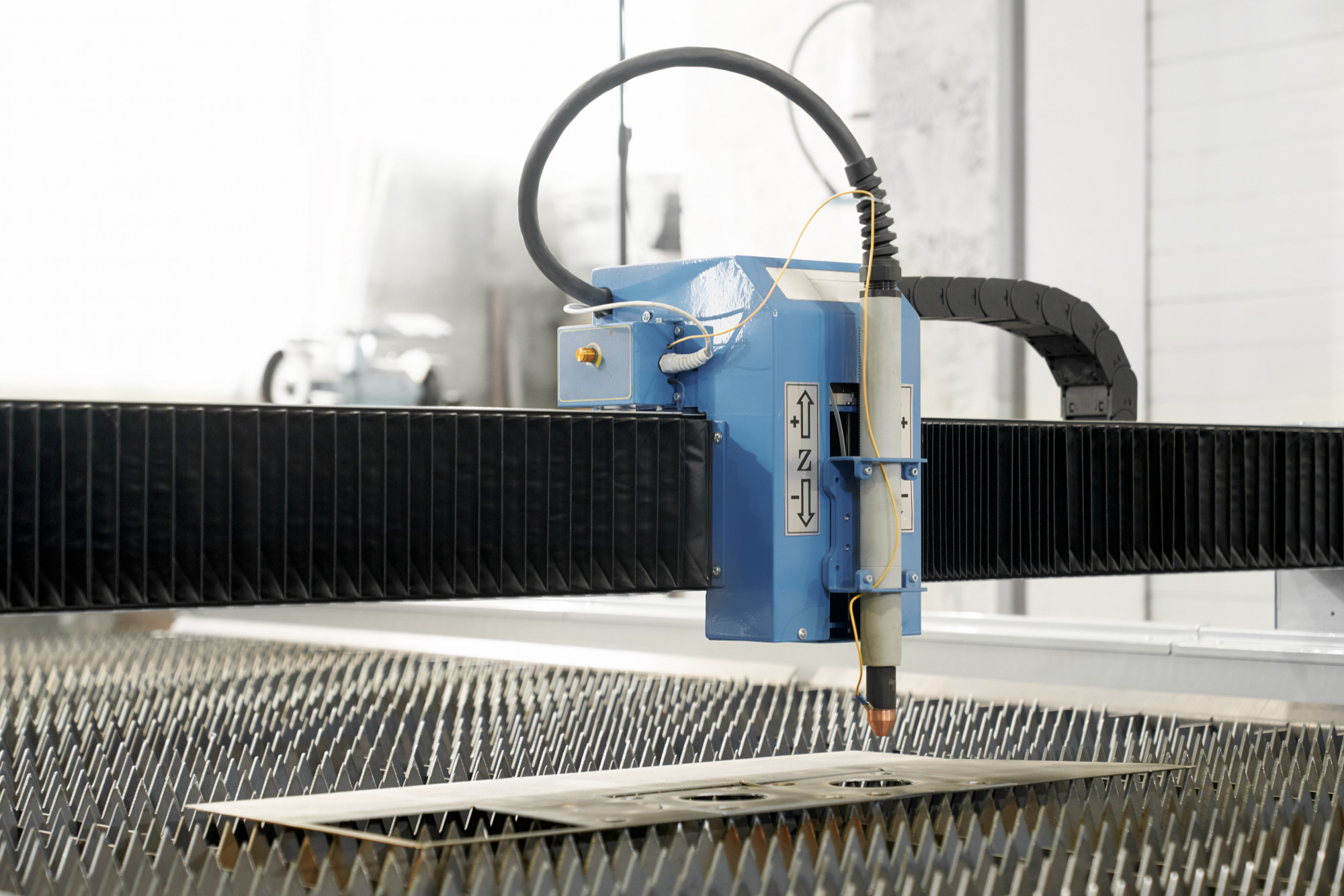

We have invested heavily into cutting edge, professional grade 3D laser scanners and supporting software to achieve ultimate accuracy and efficiency. We use advanced 3D laser scanning technology from Trimble to capture as-built conditions with unrivalled precision and efficiency. Unlike traditional measurement methods that rely on tape measures, manual notes, or limited survey tools, our scanning process eliminates human error, drastically reduces site time, and delivers complete, accurate digital models ready for engineering and fabrication.

Perform 3D laser scans of structures, facilities, or equipment

Process scan data into a structured point cloud

Create precise 3D models, engineering drawings

Fabricate components based on the

3D model

By adopting advanced 3D scanning, we deliver:

We offer comprehensive scanning and data processing on both our fabrication projects as well as a stand-alone engineering service. Call us on 02 4647 1021 to discus how laser scanning can be of benefit to your next project.