We are your trusted partner for contract manufacturing. With a full suite of in-house services, we provide precision, efficiency, and reliability from concept through to delivery. By keeping every stage under one roof, we guarantee strict quality control, fast turnaround times, and seamless project management.

Our state-of-the-art CNC laser cutting machines deliver high precision and repeatability across a wide range of materials. With a bed capacity of 1500 x 6000mm, we can handle both small intricate components and large sheet requirements with ease. This capability allows us to produce complex profiles with exceptional accuracy, while minimising waste and maximising efficiency.

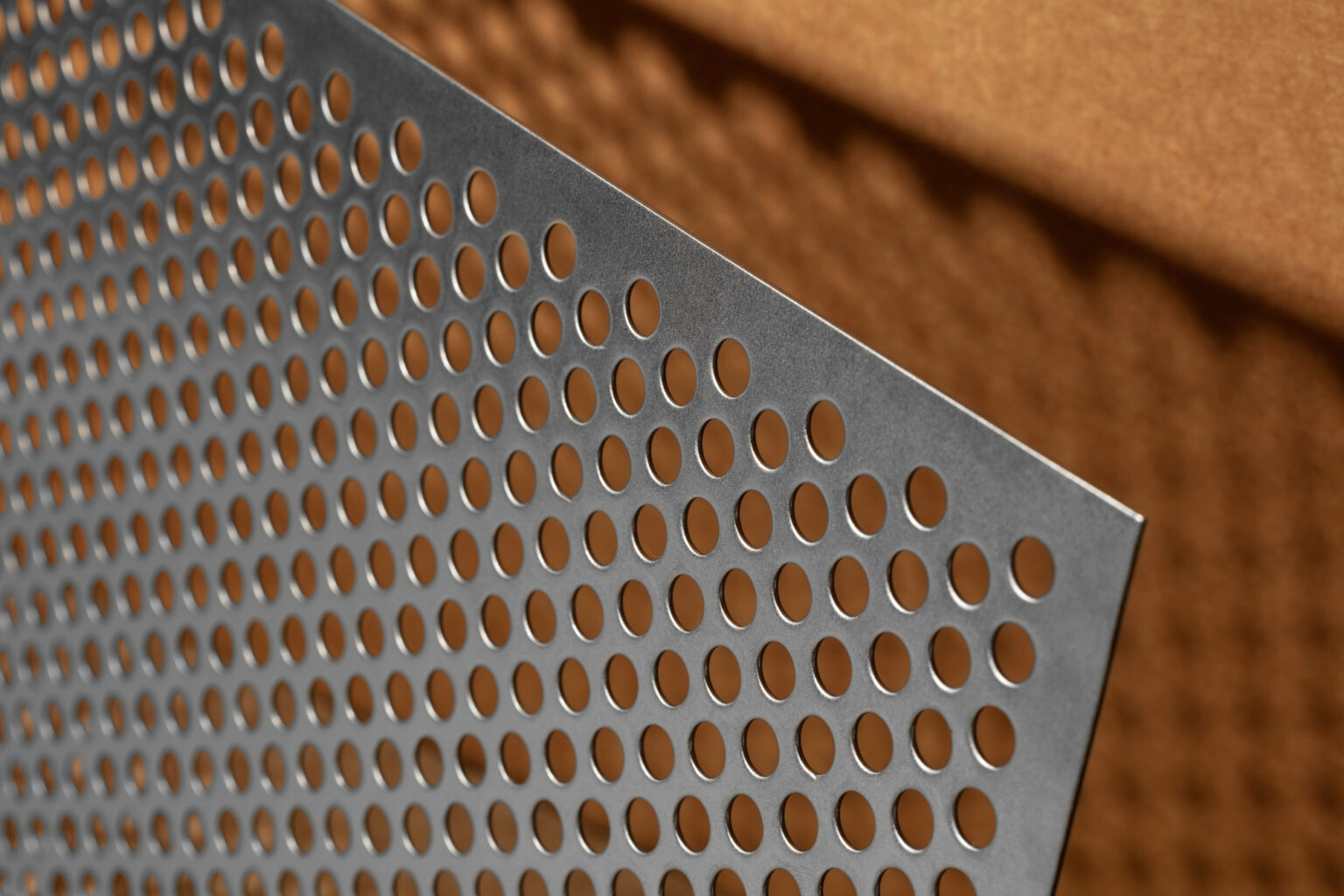

We provide versatile punching solutions for a variety of applications, from simple slots and perforations to highly complex, custom patterns. CNC turret punching is an efficient way to process large runs, ensuring consistency and cost-effectiveness.

Our press brake systems are backed by an extensive tooling library, including custom-made tooling designed in-house. This means we can achieve even the most challenging profiles and bends, while maintaining precision and repeatability. No matter the complexity of the design, we have the tools and expertise to deliver.

Our team of experienced fabricators and certified welders provide high-quality assemblies to meet the strictest industry requirements. We offer MIG, TIG, and Laser Welding to suit a variety of materials and applications — from lightweight components to large, structural assemblies.

With advanced machining equipment, we produce high-performance parts with tight tolerances and superior surface finishes. Our CNC machining services support both one-off components and high-volume production runs.

We offer efficient stud welding services for strong, permanent and invisible fastening solutions. This process ensures clean finishes and high structural integrity — making it ideal for architectural, industrial, and fitout applications.

Our precision laser welding delivers clean, low-distortion welds with a high-quality finish. It’s particularly effective for thin materials, intricate designs, and applications where both strength and appearance are critical.

Our CNC pipe bending capabilities provide accurate, repeatable bends in a range of diameters and materials. Suitable for architectural, industrial, and transport applications, we can produce both standard and complex pipe geometries to exact specifications.

Our in-house design team offers complete drafting support, from initial concepts to production-ready drawings. Using the latest 3D modelling and 2D drafting software, we ensure clarity, accuracy, and seamless communication throughout the design and manufacturing process.

At Alpine, we combine cutting-edge technology with more than 30 years of industry expertise to deliver services that meet the highest standards of quality, compliance, and performance. Whether you require a single specialised process or a complete end-to-end manufacturing solution, we have the people, technology, and experience to make it happen.